Just imagine if your industrial operations ran smarter, smoother and with fewer unexpected breakdowns. It would be amazing, right!? This imaginary world is not just reacting to all problems, but proactively they’re preventing them. It is not any science fiction, but it is the reality ushered in by Smart valve integration. Smart valve integration is a game-changer for real-time diagnostics and predictive maintenance.

For decades, different valve products have played a vital role in industrial processes. They are heroes of industrial processes, which control the flow of gases and liquids. Traditional valve solutions often rely on manual checks and routine services. For your industry challenge, if you use traditional valve solutions, it can lead to unexpected failure and cost downtime. This is where the “smart” comes in.

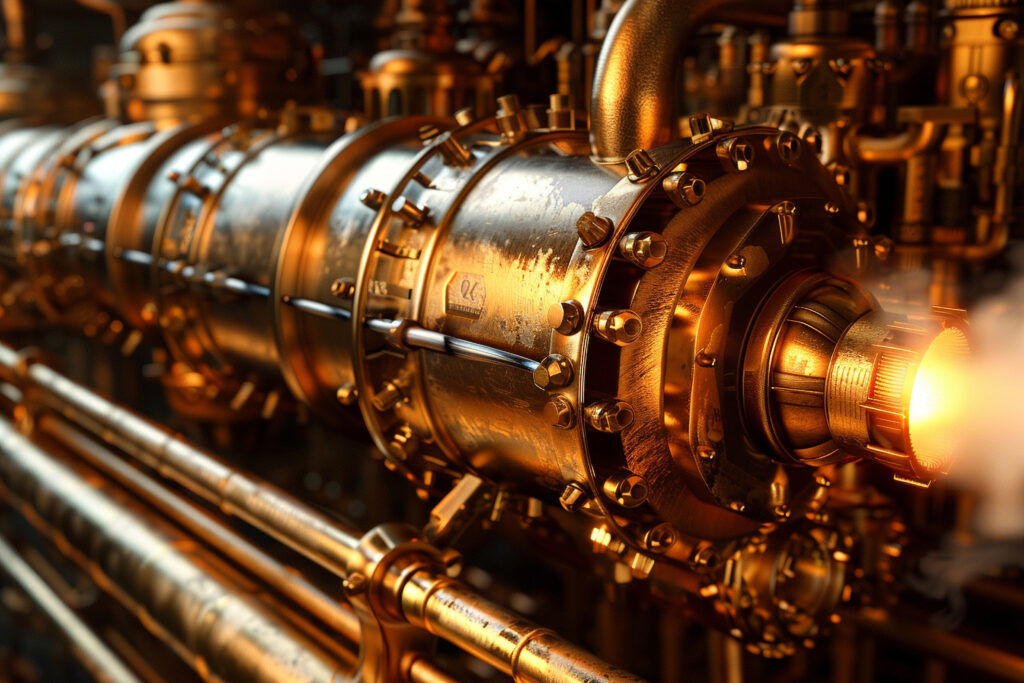

Smart valves are digitally enhanced valve systems equipped with actuators, sensors and communication interfaces. These components are used to collect real-time data about valve positions, their pressure, temperature, flow rate and wear levels.

Unlike traditional valves, smart valves automatically communicate their conditions to the central monitoring system. It enables continuous performance tracking and remote operations.

Real-time diagnostics have an X-ray vision of your valve’s health. It helps you to receive immediate alerts about valve performance and deviations. Instead of waiting for any failure, it gives instant alerts as if your valve is fully open, or any unexpected pressure drop in your valve, etc. Real-time data provides instant insights into the valve’s health, such as:

Smart valves continuously monitor valve position, flow rate, valve’s pressure & temperature, and seal integrity. This immediate visibility reduces the impact of potential problems.

Smart valves help you to overcome different challenges like corrosion, vibration, extreme environments or limited access. It helps to overcome different challenges and support reliability by providing:

Setting up real-time diagnostics tells you what the current situation is, and predictive maintenance takes further steps. It is forecast that it will likely happen next. Predictive maintenance uses machine learning and analytics to forecast when a valve may fail, which means:

In the basic term, it can directly increase productivity, cost savings and also enhance safety across the industrial system. According to the usage data, smart valve systems can suggest exact interval services, rather than relying on a generic maintenance schedule.

In simple terms, we can say a smart valve is a technological upgrade in how the industry manages its assets. It can help you to empower your businesses with unpredictable control, insight and efficiency levels. Smart valves are beneficial products for oil & gas, water treatment, and chemical processing industries.

Smart valve systems will become standard future that aim for zero-downtime performance and environmental compliance.

When we compare today’s competitive and dynamic environment, adopting a smart valve becomes necessary. Real-time diagnostics and predictive maintenance give operators the tools they need to stay ahead and reduce costs.

Investing a smart valve solutions for your industry is not only about the technology, but it will make you future-ready for maritime operations.